YYQW Series Industrial Gas Diesel Oil Fired Thermal Oil Boiler

YY(Q)W series thermal oil boiler, this series thermal oil boiler adopts three-return round tube structure with sufficient arrangement of heating surface to reduce the heat load on the surface of the tube, which makes the thermal oil safer to use. ZOZEN YY(Q)W series thermal oil boiler can supply heat up to 320℃ stably under low pressure environment, with precise temperature control and high heat energy utilization. At the same time, this series of thermal oil boiler adopts the horizontal structure of the whole factory, the compact structure greatly saves the floor space of the boiler room, while the installation cycle is short, the boiler operation and maintenance is convenient.

In addition, it can be customized according to user requirements. Therefore, it is widely used in petroleum, chemical, textile, printing and dyeing, plastics, food and other industries, and has been trusted and recognized by the majority of customers.

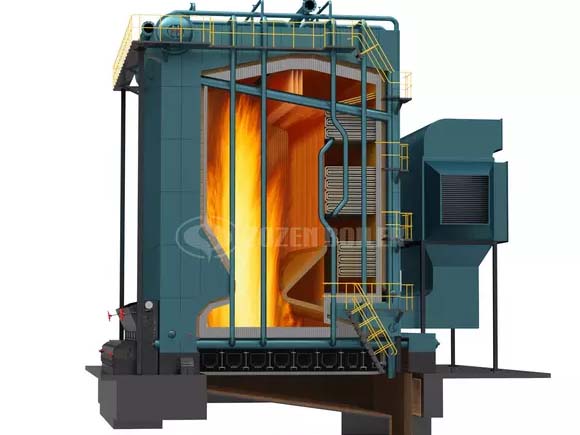

YYQW series boiler adopts horizontal three return structure, the heating surface is mainly composed of inner coil radiation heating surface and the convection heating surface composed of inner coil and outer coil, the structure is very compact. Thermal oil boilers price is reasonable, the fuel in the combustion chamber combustion and heat release, heating surface to absorb most of the heat, flue gas into the convection heating surface and heat transfer. Finally, the induced draft fan sends the flue gas to the chimney until it is discharged into the atmosphere. This boiler system has high utilization rate, convenient operation and maintenance, perfect control system, and energy saving, environmental protection, safety, is the ideal heating equipment.

When the horizontal thermal oil boiler is in operation, the fuel burns and emits heat in the combustion chamber formed by the inner coil. After the radiant heating surface absorbs most of the heat, the high-temperature flue gas enters the convection heating surface for heat exchange. The flue gas after heat exchange is discharged through the flue gas outlet of the furnace body. Enter the air preheater and fully exchange heat with the air. After the heat exchange, the flue gas enters the condenser and exchanges heat with the water. Finally, the temperature of the flue gas is reduced to below 100°C and discharged into the atmosphere through the chimney.